| Acid

Corrosive

Acid corrosive can be used in the surface treatment

of aluminum alloy. The technology was introduced from

aluminum surface processing technology in Japan, and

later on, it was put into practice and improved by and

by. Now it yields good results.

1. Characteristic:

1.1 The operation is simple and safe. The trough liquid

has a good stability and long service longevity.

1.2 The components are unique. And the operation conditions

are flexible and controllable.

1.3 The corrosion is even, and the amount of dissolved

aluminum is low. The aluminum consumption for one ton

of aluminum items is less than 8kg (about one fourth

of the aluminum consumption of alkali corrosion), thus

the production cost is reduced.

2. Technical Parameters and Operation Conditions:

2.1 Process and Solution Composition

Degreasing— water-washing — acid corrosion

— water-washing — alkali corrosion—

water-washing — neutralization — water-washing

— oxidation

Ammonium acid fluoride: 50-60g/1

Accelerant: 40-50g/1

Stabilizer: 60-70g/1

Operation temperature: 40-450C

Treatment time: about 4-6min (the treatment time can

be changed when needed)

Fixed work points: 6.5-8.5

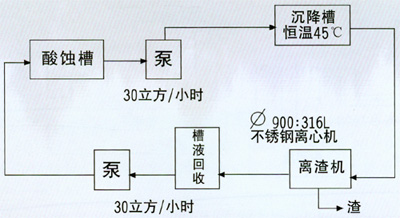

Due to that there will exist the floating matters and

deposits during the production process, it is required

that the following ancillary facilities should be set

and the sketch map is as follows:

2.3 Trough Liquid Maintenance:

2.3.1 Control the operation points to be between 6.5-8.0

according to the analysis result. Add 4-6kg of stabilizer

and 2-4kg of accelerant accordingly while adding ammonium

acid fluoride.

2.3.2 For each production batch under normal conditions,

add ammonium acid fluoride, stabilizer and accelerant

for at least two times.

2.3.3 Keep the suspension in acid corrosion trough to

the least degree, and control the operation temperature

according to the technical requirements.

3. Related Products:

For convenience, stabilizer and accelerant are packed

in a mixed way, and the product No. is (F200-1).

3.1 Technical Parameters:

Ammonium acid fluoride: 55-65g/1

F200-1 acid corrosive: 65-75g/1

Intermediate: 1g/1

Operation temperature: 40-450C

Treatment time: about 4-6min

Fixed work points: 6.5-8.0

3.2 Production Consumption: 3-3.5kg of acid corrosive

is consumed to produce one ton of section bars, or add

8-12kg of acid corrosive when 100kg ammonium acid fluoride

is consumed. The operation points can be determined

according to the method for the first type of products.

4. Analysis Method:

Add 10ml of trough liquid to a 250ml conical flask,

and add 50-100ml of pure water. Rock the conical flask

and make them mix evenly. Then drip 3-4 drops of phenolphthalein,

and then titrate the trough liquid with 1N NaOH standard

solution till the end point (when the solution turns

pink).

Calculation of operation points: NNaOH VNaOH

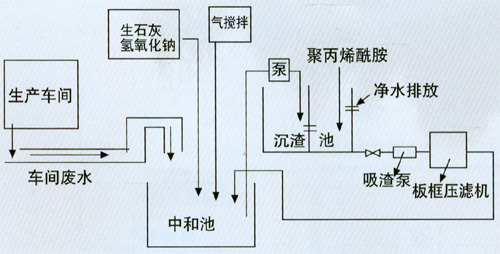

5. Suggestions for Requirement of Environment

Protection: (Waste Water Treatment)

The waste water contains fluorine ions when ammonium

acid fluoride is used in the aluminum surface treatment

process. Therefore, the fluorine ions should be treated

in the waste water treatment. The suggestions are as

follows:

5.1 The waste water is discharged into

the neutralization tank. pH value is adjusted at 3-4

with NaOH and then adjusted at 7-8 with CaO.

5.2 The waste water is drawn to the higher tank, and

polyacrylamide diluent (about 20-30g polyacrylamide/m3)

is added.

5.3 The sedimentation at the bottom of sedimentation

tank is separated from water by percolator, and the

sedimentation is packed in a bag, and the water is discharged

into the neutralization tank.

5.4 Users can treat the waste water according to the

company’s criterion, and discharge the waste water

when it meets the related contamination-discharging

criterion of the country.

|