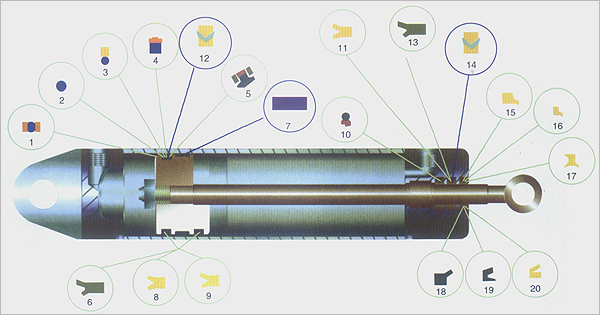

Note:

1 is 'O' shaped circle, 'O' shaped circle is produced by butyronitrile oil resistant rubber.

2 is 'O' shaped circle, according to GB1235.76 and GB3452.1-92

3 is 'Glyd ring'.

4 is the combination of rectangle low hardness oil resistant rubber and high hardness oil resistant rubber products.

5 is 'anti-dust ring', adopts filling tetrafluoroethylene ring as the friction facing.

6 is 'YX' type sealing ring for hole, produced by butyronitrile oil resistant rubberor polyester rubber.

7 is polyformaldehyde bearing ring.

8 and 9 are 'Y' type sealing ring for hole, produced according to GBl0708.1-2000.

10 is 'Step Seal', is the combination of filling polytetrafluoroethylene righ and 'O' ring.

11 is 'Y' type sealing ring for axle.

12 is rubber folder fabric combination, sealing ring for hole, and produced according to National Standard HG4-337-66, GB10708.1-2000.

13 is 'YX' type sealing ring for axle.

14 is rubber folder fabric combination, sealing ring for axle.

15, 16, 17, 18, 19 and 20 are anti-dust ring.

Selection of materials

Name |

Code |

Main characteristic |

Operating temperature

(℃) |

Main usage |

Polyoxymethylene |

POM |

Resistant to oil, heat and good abrasive resistance and compression strength, favorable shock resistance, has good self-lubricating property, good dimensional stability. |

-40~120 |

Used for production of bearing ring, rider ring, retainer ring, shaft sleeve, slide block etc. |

Poly(tetrafluoroethylene) |

PTEE |

Good chemical stability, resistant to heat and cold, resistant to oil, water, gas, chemical products and various media; higher mechanical strength, resistant to high pressure, good abrasive resistance; low frictional coefficient, good self-lubricating property. |

-55~260 |

Used for the production of wear-resistant ring, rider ring, retainer ring, it is widely used in metallurgy, petrifaction, engineering machinery and light industrial machinery. |

Phenolic cloth insertion |

WR |

Has high warp-wise tensile strength and general dielectric performance, low water absorbability. |

-40~130 |

Suitable for retainer, sealing reel and bearing ring of high speed bearing. |

Nitrile rubber |

NBR |

Resistant to oil, heat, good abrasive resistance, widely used for manufacturing of sealing products, not suitable for gear oil of phosphate series hydraulic oil and containing polar additives; |

-40~120 |

Used for manufacturing of O shaped ring, oil sealing, suitable for sealing of generaly hydraulic and pneumatic system. |

Fluororubber |

FKM |

Resistant to heat, acid, alkali and other chemical products; resistant to oil, used in all lubricants, gasoline, hydraulic oil and synthetic oil. |

-20~200 |

Suitable for the sealing of heat-resistance, chemical products and flame resistant hydraulic oil, widely applied in metallurgy, electricity and other industries. |

Rubber composite material |

RP |

With high flexibility and strength, other properties are same as NBR. |

-30~120 |

Used for manufacturing of O shaped ring, Y shaped ring, anti-dust ring etc, suitable for the sealing in operating machinery and high-pressure hydraulic syste. |

Cloth insertion rubber |

FAB |

It is formed by NBR and cotton, with high strength, good wear-resistance, oil resistance is lower than NBR, other properties are same as NBR. |

-30~100 |

Used for manufacturing of clothing insertion and sealing, suitable for sealing in engineering machinery, metallurgical equipment and high pressure system. |

Nylon |

PA |

Resistant to oil, heat, good wear-resistance, high compression strength, good shock resistance, bad dimensional stability. |

-40~120 |

Used for production of rider ring, bearing ring, junk ring and retainer ring. |

Polyurethane |

PU |

Excellent resistant oil and heat, excellent wear-resistance, high compression strength, good shock resistance. |

-40~100 |

Used for production of Y shaped ring and anti-dust ring etc, widely applied in sealing of engineering machinery and various hydraulic system. |

Ethylene/propylene copolymer |

EPDM

or EPM |

Resistant to weather, anti-aging in the air, modest effects in oil resistance. |

-50~150 |

Used in sealing of refigerator and refrigerating machinery. |

|