|

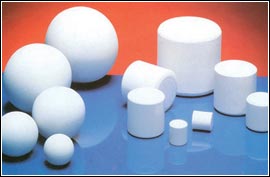

The high aluminum porcelain ball is high density, high mechanical

strength. It has fine abrasion resistance. It can be used in machine,

electrons, space fleet industry. We also produce various pipes,

rings, bars, ridges , plates and parts.

The high aluminum porcelain ball is high density, high mechanical

strength. It has fine abrasion resistance. It can be used in machine,

electrons, space fleet industry. We also produce various pipes,

rings, bars, ridges , plates and parts.

The technical index of high aluminum porcelain ball

|

Chemical ingredients

|

Physical properties

|

|

ingredients

|

Value |

Item

|

Value |

|

Al2O3

|

80-95% |

specific gravity g/cm3

|

2.8-3.5 |

|

SiO2

|

3-17% |

specific heat cal/g  |

0.17-0.20 |

|

MgO

|

0.5% |

compressive strength

|

>1500 |

|

Fe2O3

|

0.3% |

hardness

|

7 |

|

CaO

|

0.2% |

abrasion ( % )

|

0.05 |

|

Na2O

|

0.1% |

water absorption ( % )

|

<1 |

SW activated porcelain ball properties

|

specifications

|

1.5mm-50mm

|

|

model

|

SW-1 |

SW-2 |

SW-3 |

remarks

|

|

appearance

|

light brown

|

light yellow-white

|

light gray

|

if the dia >  19,

it should be tapped |

|

tap density g/cm3

|

0.85  0.05 |

1.2  0.1 |

2.0  0.2 |

|

Al2O3 W/%

|

85 |

40 |

40 |

|

activated content

|

NiO.MoO3 |

NiO.WO3 |

CoO.MoO3 |

|

compressive strength N/p

|

>60 |

>130-2500 |

>130-2500 |

SW activated porcelain ball catalytic properties

| model |

SW-1 |

SW-2 |

SW-3 |

reaction temperature  |

275 |

300 |

300 |

320 |

350 |

300 |

320 |

350 |

| hydrogen partial pressure MP |

3.0 |

3.0 |

3.0 |

3.0 |

3.0 |

3.0 |

3.0 |

3.0 |

| liquid airspeed h-1 |

1.0 |

10 |

4.2 |

4.2 |

4.2 |

4.2 |

4.2 |

4.2 |

| hydrogen/oil ratio |

600 |

600 |

450 |

450 |

450 |

450 |

450 |

450 |

| S W% |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

| alkene W% |

27.5 |

27.5 |

27.5 |

27.5 |

27.5 |

27.5 |

27.5 |

27.5 |

| desulfuration rate % |

76 |

95 |

40 |

60 |

77 |

36 |

54 |

63 |

| alkene saturated percent % |

58 |

95 |

10 |

33 |

45 |

7 |

19 |

42 |

Wearproof ball

It is high efficiency, low abrasion, high

pure, low current operation.

Wearproof ball technical index

|

Al2O3

|

55-65-95% |

|

specific gravity

|

2.7-2.8-3.7g/mm3 |

|

hardness

|

8.5 |

|

compressive strength

|

1690MPa |

|

water absorption

|

0.2% |

|

abrasion

|

0.05% |

|

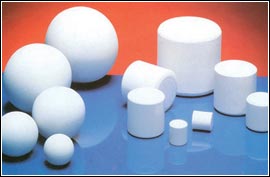

The high aluminum porcelain ball is high density, high mechanical

strength. It has fine abrasion resistance. It can be used in machine,

electrons, space fleet industry. We also produce various pipes,

rings, bars, ridges , plates and parts.

The high aluminum porcelain ball is high density, high mechanical

strength. It has fine abrasion resistance. It can be used in machine,

electrons, space fleet industry. We also produce various pipes,

rings, bars, ridges , plates and parts.