Actmix® Accelerant DOTG-75

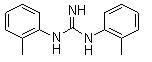

Accelerant DOTG

Active ingredients |

1,3-di-O-tolylguanidine

Molecular Formula: C15H17N3

Molecular Weight: 239.32

CAS RN: 97-39-2

EIENCS RN: 202-577-6 |

Properties:

DOTG can cause slow curing speed and thus should be used together with anti-aging agent. DOTG has no crocking in vulcanized rubbers.

NR: 0.8~1.2 poses and 2.5~4 poses sulphur used together

SBR: 0.1~0.4 poses and 1~1.5 poses thiol and 1.5~2.5 poses used together with sulphur

NBR: 0.05~0.4phr and 0.8~1.5phr sulfenamide Accelerant and 1.5~2.4phrused together with sulphur.

|

Typical Data:

M.P.: 175-178 oC

Density: 1.1

Purity: min 96%

Ash: Max 0.5%

Volatiles: Max 0.5 %

63µm sieve residue: Max 0.5 % |

High-disperse master batch

|

Product Name |

Active content

% |

Color |

Filtration

(micron) |

Carrier type |

Mooney viscosity ML(1+4)

50°C Typical Value |

Density

Typical Value |

Actmix® DOTG-75 |

75 |

offwhite |

140 |

ethylene propylene rubber/EVM |

30-50 |

1.10 |

*Carrier type can be customized. Except for ethylene propylene rubber/EVM, other carriers, such as nitrile rubber, styrene-butadiene rubber, acrylate rubber and polyepichlorohydrin rubber can be used.

Safety & Toxicity:

Pls. refer to related MSDS

Packing & Storage:

25kgs/carton lined with PE bag; 600kgs/pallet

Stored in cool and dry place. Shelf life is 2 yrs in sealed original package. |

Compared with traditional powdered DOTG, Actmix® DOTG-75 has the following advantages:

Raw materials 38µm are all under sifting, but no dust appears with master batch

master batch DOTG-75 is pre-dispersed with rubber carrier, thus can effectively ensure the activity of DOTG.

No clay domain appears with master batch at room temperature

Has low Mooney viscosity at low temperature such as 50°C to improve disperse quality

While granulation, master batch can filtering to lower rejection rate.

Has good compatibility with different rubbers |