Actmix® Antiscorcher CTP-80

Antiscorcher CTP(PVI)

Active ingredients

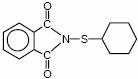

|

N-(Cyclohexylthio)phtalimide

Molecular Formula: C14H15O2SN

Molecular Weight: 263.1

CAS RN: 17796-82-6

EIENCS RN:241-774-1 |

Properties:

Active ingredients CTP can delay the initial vulcanization of natural rubber and dialkene series synthetic rubbers while won't prolong the curing time. It can improve the processing safety of vulcanized rubber.

Used for natural rubber and synthetic glue stuff(tire/conveyer belt, shoe sole, mould pressing and extrusion products)

Use level: 0.2 ~ 2.0 |

Typical Data:

M.P.: 85°C

Density: 1.2

Purity: 98%

|

High-disperse master batch

|

Product Name |

Active content

% |

Color |

Filtration

(micron) |

Carrier type* |

Mooney viscosity ML(1+4)

50°C Typical Value |

Density

Typical Value |

Actmix® CTP-80 |

80 |

beige |

500 |

ethylene propylene rubber/EVM |

30-50 |

1.22 |

*Carrier type can be customized. Except for ethylene propylene rubber/EVM, other carriers, such as nitrile rubber, styrene-butadiene rubber (SBR), acrylate rubber etc.

Safety & Toxicity:

Pls. refer to related MSDS

Packing & Storage:

25kgs/carton lined with PE bag; 1 ton/pallet.

Stored in cool and dry place. Shelf life is 2 yrs in sealed original package. |

Compared with traditional powdered CTP, Actmix® CTP-80 has the following advantages:

Raw material 60µ are all under sifting, but no dust appears with master batch

No clay domain appears with master batch at room temperature

Has low Mooney viscosity at low temperature such as 50°C to improve disperse quality

While granulation, master batch can filtering to lower rejection rate.

Has good compatibility with different rubbers |