5, and operation procedures and the use of methods

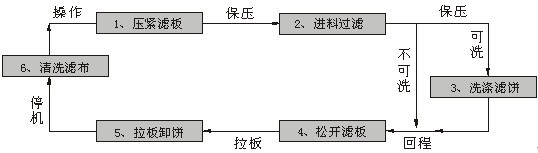

Filter press operating procedures according to the following process:

1, clamping plate

The "Operation / packing / Pull Plate" switch appropriated for "operation" position,

press the "pressed" button, the piston rod forward, pressed plate,

reaching the maximum pressure 25Mpa calibration, the motor automatically shut

down. The "Operation / packing / Pull Plate" switch appropriated

for "packing" position, the filter press into the auto-packing state.

2, feed filters

After packing into the state, check the pipe valve opening and closing

conditions, to confirm correct start feeding pump, slowly open the feed

valve, slurry through the feed thrust plate holes into the filter room,

in the provisions of under pressure to achieve pressure filtration to form

a cake.

3, washing cake (suitable for UK-type filter press)

Filtering is completed, wash water from washing into the hole-pass filter

indoors, infiltration filter cake layer on the cake for washing. Can be

further recovered by washing the filter cake in the active ingredient,

or remove these harmful ingredients. For on the cake to blow, you can pass

into the hole from a compressed air cleaning to remove the part of the

filter cake moisture.

4, release plate

The "operating / holding pressure" switch appropriated for "operation" position,

press the "return" button, piston return, plate release. Pistons

back to back in place, pressed board hit limit switch automatically stops,

on the return end.

5, pull board cake discharge

Manual pull board cake discharge: The pull-plate followed by manual cake

discharge.

6, cleaning cloth finishing

La plate discharge after the residues left in the cloth on the need to

clean up the filter cloth should be re-finishing flat to begin the next

cycle of work. When the filter cloth of the retention capacity of recession,

it would take on the filter cloth cleaning or replacement.

|