6, filter cloth processing and installation

method

This section is based on plate thickness 60mm,

thickness 30mm filter cake as an example. Due to

the different models, as well as a variety of working

conditions under the filtration process is different

from the production of cloth different ways, the

user can consult to my company's technology department.

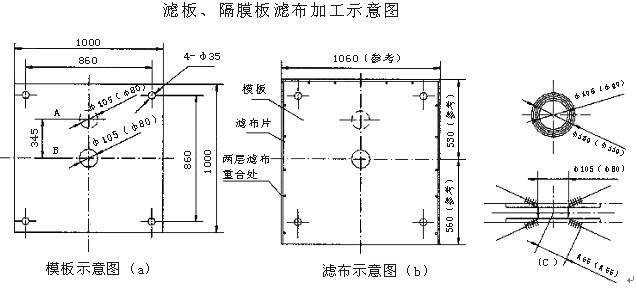

(1) cloth cover processing methods

1, the primary reference template diagram (a)

shows, using plywood or other material produced

a template, using metal plates around the hole

wrap to prevent the electrical ferrochrome work

Tanghuai template.

2, will be cut to 1080 × 1100mm as a filter

cloth filter cloth films, cloth cut to 410 × 70mm

as a set of intermediate connecting ring.

3, will reveal the width of 10mm triangular cloth

piece around and used industrial sewing machine

stitches (double side cloth reinforcement, pay

attention to rectangular filter cloth, sewing cloth,

after a good film can be found in Figure (b), dimensions

in brackets as a reference size).

4, in the cloth-chip hot-hole φ5

three weeks or so (electric iron according to the

size of the head diameter), hot in the single-layer

filter cloth, the location can refer to diagram

(b).

5, the template on the filter cloth on-chip, power

chrome iron hot holes and washed out the middle

hole. Washing hole hole hole location and the number

of actual plate sizing.

6, take two tablets and an intermediate

connection filter cloth cloth cloth cloth first

intermediate connection piece sewing circle around

the center hole diameter of approximately φ130 or so,

and then gradually to sew 3-4 hole circle, until

the inner ring diameter of φ105; and then re-join

the middle of lap two stitches Junction; the end,

the same method to connect the middle of a circle

with another cloth pieces stitched together. (See

Figure (c)

7, A-hole that motivated material I, B Kong, said

in the Inlet. Under normal circumstances, the two

only one, the two feeding methods filter cloth,

its processing and installation the same way.

(2) Cloth film processing methods

1, will be cut to 1060 × 2190mm

as a filter cloth filter cloth on their processing

methods see Figure (d) and (1), supra.

2, A, B indicates that the feed hole, C, D, said

feed hole upward mobility. Can only be opened at

the same time A, B or C, D Hole.

3, electricity ferrochrome iron out the feed hole

and washed hole, washing hole hole hole location

and the number of actual plate sizing.

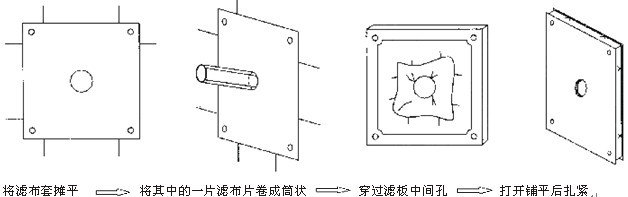

(3) installation method

1, the installation cloth cover, it will be one

of the side of cloth rolled into cylindrical shape,

and then through the plate center hole, and then

start pave the way, with a plate on the truss with

a belt filter cloth (see Figure e : filter cloth

cover installation diagram).

Cloth cover installation diagram (e)

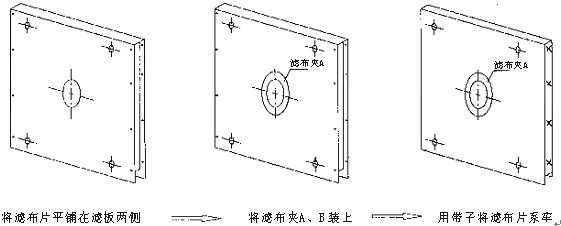

2, installation of filter cloth films, usually

use cloth folder (as shown in Figure g folders

made of polypropylene filter cloth, filter cloth

made of stainless steel clip, its slightly different

shape with the figure g, this manual does not indicate

otherwise) a fixed , the installation method see

Figure f and Figure g.

Cloth piece installation diagram (f)

1, filter cloth clip A 2, cloth folder B 3, bushing

cloth clip 4, filter cloth 5, plate

Cloth folder

diagram (g)

(4) The filter cloth production and installation

of Attention

1, electric ferrochrome can be used 500W.

2, be careful when ironing cloth, filter cloth

filter part of the not burning, or else there are

holes cloth, slurry through the filter cloth is

easy, resulting in a fluid pressure difference

on both sides of muddy and not the same, and in

severe damage to filter board.

3, filter cloth to sew well, otherwise used for

a period of time, the stitching easy to crack,

resulting in a turbid liquid.

4, sewing machine pins should choose a reasonable,

otherwise easily leak from the pin at material.

5, cloth worn on-chip to be away from the rope

handle hole and tap position, and ensure the smooth

cloth bag at the plate to the outside.

6, the user hole in the cloth, should fully understand

the physical properties of the filter cloth. For

easy to shrink cloth and must be shrunk, a fluid

port (lotion mouth) hole size of plate holes about

70%. When installing filter cloth, filter cloth

should pay attention to holes to be aligned with

the plate hole, without folding, so as to avoid

leakage. Filter cloth around the top and the plate

ends is greater than 30mm is better. Cloth to use

for some time to harden, its filtration performance

degradation, this cloth should be regularly checked

and any hardening phenomenon, then with the corresponding

to the low concentration of weak acid or weak base,

and (soaked 24 hours), to restore its.

|