Elution machine

Elution machine realizes fully anti-vibration structure, effectly solved the vibration problems in dewatering of the washing machine.

1. Attention

Transportation, handling

1) The handling of the machine must be undertook when adding the transport fixed metal.

2) Avoid strong impact so as not to damage the machine.

3) Handling in rain, be sure to stamp the sheets to the machine to prevent rainwater, espercially the control box.

4) When the crane lifting, set the wire rope fixed at four lifting holes in the machine.

Installation

1. Base

Installation of the machine, if the base can bear the weight of the machine and the ground is flat, special base is not needed.

2. Installation space

The surroundion of the machine should have enough space.

3. Installation

The machine is placed in the ground, then tighten the bolt.

Attention

Do not place elastic material like rubber pad, this will exacerbate the vibration of the machine.

4. The romoval of the transport fixed metal plate

5. The installation of inlet water, steam tube.

1) Install inlet water tube channel of inlet water, soup tube.

2) Installation of steam tube channel.

Attention

Please install vlave between the channels besides inlet water mouth

Attention

1) The machine must contact the ground.

2) Direction of rotation: This machine is variable frequency drive, so the direction of rotation is unrelated to power.

3) Do not perform insulation resistance tests, otherwise you will lose a computer and inverter.

Specifications and parameters of the machine

| Model parameter |

XGQ15F |

XGQ30F |

XGQ50F |

XGQ80F |

XGQ100F |

| Treatment capacity |

15Kg |

30Kg |

50Kg |

80Kg |

100Kg |

| Roller dimensions |

Φ650×450 |

Φ900×480 |

Φ 970×680 |

Φ1080×760 |

Φ1200×820 |

| Cubage |

149lit |

305lit |

523lit |

746lit |

926lit |

| Washing rotation speed |

50rpm |

40rpm |

35rpm |

33rpm |

31rpm |

| Uniform distribution rotation speed |

90rpm |

72rpm |

75rpm |

70rpm |

65rpm |

| Middle dehydration |

450rpm |

420rpm |

380rpm |

350rpm |

310rpm |

| High dehydration |

890rpm |

780rpm |

760rpm |

680rpm |

680rpm |

| Power supply |

Standard:380+N-3PH-50HZ |

| Motor power |

2.2Kw |

3Kw |

4Kw |

5.5Kw |

7.5Kw |

| Inverter |

3Kw |

4Kw |

5.5Kw |

7.5Kw |

11Kw |

| Heating power |

12Kw |

24Kw |

30Kw |

|

|

| Steam consumption ratio |

0.9 Kg/ Kg |

| Inlet water tube |

1” |

1” |

3/2” |

3/2” |

2” |

| Steam tube |

1” |

1” |

1” |

1” |

3/2” |

| Soap tube |

1/2” |

1/2” |

1/2” |

3/4” |

3/4” |

| Dimensions |

900×850×1200 |

1100×1300×1500 |

1600×1580×1800 |

1900×1580×1800 |

1900×1680×1900 |

| Weight |

400 Kg |

890Kg |

1800Kg |

2600Kg |

3200Kg |

Instruction

XGQ15F,XGQ30F,XGQ50F has two heating types, one is steam heating and the other is hot water auxiliary electric heating type.

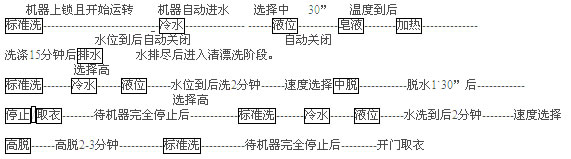

3. Operation methods

The machine has two operating methods, one is manually operation and the other is automatic operation.

The preparation:

1. Put the washing material according to the capacity of the machine.

2. Open the valve of the inlet water and steam tube of the machine.

3. Prepare the detergent.

4. Open the air compressor.

5. Turn the power on.

A. Manual operation

The above is the basic operation, just for reference. |