| Decabromodiphenyl Ethane |

| Product data: |

Decabromodiphenyl Ethane |

| Description: |

This is our new-developed neo-type additive fire retardant of bromine series. It has very good thermal stability, high bromine content and is hardly soluble in all solvents. It can be used in a wide range of styrenic polymers, engineering resins, wire & cable covers, insulator, elastomer and thermosetting plastics as well. |

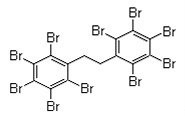

| Chemical structure formula: |

|

| CAS No: |

84852-53-9 |

Molecular formula: |

C14H48Br10 |

Molecular weight: |

971.2 |

| Odour: |

Odourless |

Melting point: |

Appr. 345℃ |

Appearance: |

White powder |

Durability: |

Thermally stable at ambient temperatures. |

| Technical demands: |

Total bromine content |

81.5% min. |

Whiteness |

90° |

Melting point |

345℃ min. |

Volatile |

0.1% max. |

Free bromine |

10ppm max |

Average particle size |

5um max. |

Appearance |

White powder |

|

| Benefits : |

1. It is a wide-ranged, white powdered and additive type fire retardant widely used. It has very good thermal stability, high bromine content and it exhibits good UV resistance. It has a lower transudation as compared to other fire retardant of bromine series, so it is especially suitable for slap-up material used to produce computer, electrograph, telephone, manifdder, household electrical appliances etc.

2. It does not send off poisonous DBDD and DBDF when thermal cracking and burning. The materials fire-retarded by it is completely meeting European dioxin ordinances and are environmentally friendly.

3. It is not acutely toxic, it is not teratogenic, and it is not harmful to fish. It is qualified for environmental protection.

4. It is quite stable for the use of systems. The engineering resins using it can be recycled during using.

5. It is reduces the disadvantageous effects compared to traditional fire retardant DBDPO and has a strong light stability and low transudation. |

| It Does Recommended: |

high polymer

fire retarded |

DBDPE Does |

Sb2O3 Does |

Materials fire retarded level UL94(1.6mm) |

PP+14% Silicate |

22 |

6 |

V-0 |

HIPS |

12 |

4 |

V-0 |

ABS |

15 |

4 |

V-0 |

PS |

14 |

5 |

V-0 |

PBT |

10 |

5 |

V-0 |

Thermoplastic elastomer |

18 |

9 |

V-0 |

XLPE |

21 |

7 |

V-0 |

Thermosetting EP |

6 |

3 |

V-0 |

Enhanced PA(Nylon 66) |

14 |

5 |

V-0 |

LDPE |

6 |

2 |

/ |

HDPE |

8 |

3 |

/ |

|

| The does may differ from above diagram during using by users; the data above is only for reference. |

| Packing and transport information : |

Packing: in 25kg WPP bag with inner PE bag 1 FCL 20#= 20MT without pallet

In 800kg big bag with inner PE bag. 1 FCL 20#= 20MT with pallet

Transport: General chemicals.

More information and MSDS, please contact us by email: sales@zijiangchem.com

|