Working Principle: Working Principle:

After being cleaned, the seed is delivered to grain storage section of the drier by hoister, the grain feeding is automatically controlled by level-sensing device, the running direction of seed in the drier forms cross current with the flow direction of hot wind (cold wind), so as to realize the entire process of preheating, drying---reversing, drying and cooling, attain the ideal preset index, and it is discharged through belt conveyer by means of grain storage section.

Features: Features:

High efficiency, energy-saving, safety and reliability;

the dried product is even with high quality, it is pollution free;

the adjustability is well, it covers a small area;

the operation, maintenance and transport are convenient. Wind temperature is automatically digitally displayed. The charge level is automatically controlled.

Application Range: Application Range:

It applies to crop drying work in food, starch, pharmacy, feeed, winery, and rapeseed industries.

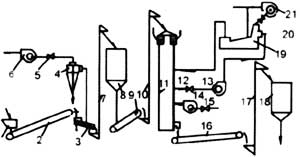

Typical process flow Typical process flow

1. Hopper 2. Belt conveyer 3. Sieve machine

4. Duster 5. Blast regulator 6. Fan

7. Hoister 8. Front storage warehouse 9. Belt conveyer

10. Hoister 11. Drier 12. Cold air blower

13. Blast regulator 14. Belt conveyer 15. Hoister

16. Rear storage warehouse 17. Air heater 18. Hot air blower

19. Blast regulator 20. Blast regulator 21. Fan

|

|

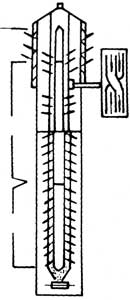

Structure schematic diagram Structure schematic diagram

Main Tower Structure: Cooling section, drying section, preheating section.

|

preheating section

drying section

Cooling section |

|

Technical Parameters Technical Parameters

|

LGH-10 |

LGH-15 |

LGH-20 |

LGH-25 |

LGH-30 |

LGH-40 |

LGH-50 |

LGH-70 |

Handling capacity T/day |

100 |

150 |

200 |

250 |

300 |

400 |

500 |

700 |

Installed capacity kW |

33-44 |

44-51 |

48-59 |

59

-68 |

52-69 |

69

-80 |

60-79 |

79

-91 |

74-04 |

104-120 |

97-123 |

123-142 |

110-145 |

145

-168 |

162-196 |

196-238 |

Extent of lowering moisture % |

5-8 |

8-10 |

5-8 |

8-10 |

5-8 |

8-10 |

5-8 |

8-10 |

5-8 |

8-10 |

5-8 |

8-10 |

5-8 |

8-10 |

5-8 |

8-10 |

Extension of lowering moisture |

14% |

Unit heat consumption KJ/KgH2O |

5862 |

Hot wind temperature ℃ |

8-10≤120 adjustable |

Highest grain temp. ℃ |

<50 |

Heating medium |

clean hot air |

Grain pollution |

none |

Non-homogeneity % |

=2 |

Crushing rate increment% |

<0.5 |

Energy consumption KJ/KgH2O |

5982 |

Heat supplier efficiency% |

>70 |

Crushing rate increment % |

<30 |

Grain vitality after dring% |

> 50 before drying |

Coal consumption kg/h |

40-93 |

93-115 |

78-148 |

148-185 |

98-185 |

185-232 |

122-232 |

232-289 |

147-278 |

278-347 |

196-370 |

370-463 |

245-464 |

464-580 |

430-696 |

696-812 |

Main tower overall size m×m |

3.4×3.13 |

3.4×3.13 |

3.4×3.13 |

3.4×3.13 |

3.4×3.13 |

3.4×4.95 |

3.4×4.95 |

3.4×4.95 |

Main tower height m |

8-10 |

10-2.2 |

9.8-11.7 |

11.7-12.16 |

14-16.74 |

16.34-17.7 |

14.4-17.64 |

17.64-19.6 |

16.1-19.64 |

19.64-21.5 |

14.64-17.64 |

17.64-19.6 |

17.2-21.5 |

21.5-23.52 |

25.5-28.48 |

28.48-30.4 |

|