Working Principle Working Principle

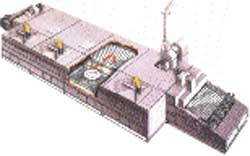

As shown in the following drawing, the material in the hopper is evenly paved on the mesh-belt by feeder, 12-60 mesh stainless steel web is adopted for mesh-belt, it is driven by driving device to move in the drier. The drying section is composed of certain units, hot wind in each unit circulates independently, partial tail-gas is discharged by special purpose moisture removing blower fan 6. The amount of exhaust gas discharged from each unit is controlled by adjustment valve 7. In the above circulation unit, circulation blower fan 5 makes the output wind enter the lower cavity of unit through side wind channel, the gas flow is heated upward through heat exchanger 4, after being distributed by distributor 3, it is blown toward mesh-belt in a reaction jet, and enters upper cavity after penetrating material. The drying process is: hot gas flow penetrates material layer to complete the process of mass transfer and heat transfer. The upper cavity is connected with blower fan inlet through wind pipe, the most gas is circulated, a portion of gas with relatively low temperature and relatively high humidity is discharged as waste gas through moisture removing pipe adjustment valve and moisture removing blower fan. In the lower circulation unit, the wind from circulation blower fan firstly enters upper cavity, it is heated downward through heat exchanger, it penetrates material layer to enter the lower cavity, the lower cavity is connected with blower fan inlet through side wind channel and return air duct, the most gas is circulated, and a portion is discharged. The upper and lower circulation units may be flexibly allocated according to need of users, the quantity of units may be selected by users.

Main Use Main Use

GDL series band drier is a continuous type drying equipment, it applies to drying flake, strip and granular materials with relatively good air permeability. It is specially suitable for materials with high water content in which high material temperature is not allowed, such as dehydrated vegetable and medical herb in pieces. The series direr has the strong points of fast drying speed, high evaporation strength and good product quality, etc.

|