Working Principle: Working Principle:

Grain enters drying box through hopper, hoister and chute, it slowly flows downward by its deadweight, drying is finished once through retarding section and drying section. Then the grain is discharged to lower screw conveyer through grain discharge mechanism, the grain is delivered back to drying box again through hoister, entering the second time of circulation. Refer to the drawing (the moment of grain entering drying section for the first time to the moment of entering the drying section for the second time is a cycle). While the grain enters the cycle, hot wind transversely penetrates the thin grain layer at drying section continuously from hot wind chamber, so that temperature of the grain layer is raised and its moisture is decreased. The waste air passing through grain layer is discharge out by the blower fan, thus the grain is dried repeatedly, till the water content of grain reaches the required standard for warehouse entrance.

The grain is not ventilated and heated at the retarding section, but certain temperature is kept, because of the temperature difference and humidity difference existing inside grain surface, partial moisture in the grain moves outward, so that the moisture inside and outside the grain tends to be balanced.

When water content of the grain reaches standard for warehouse entry, open the grain discharge gate, the grain no longer enters drying box, it directly enters grain discharge pipe through head part of hoister, and it is discharged out of the machine.

Flow Chart: Flow Chart:

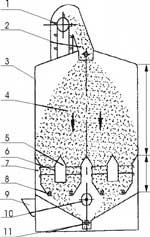

1. Hoister 2. Chute 3. Drying box

4. Grain 5. Hot wind chamber 6. Sieve plate

7. Waste air chamber 8. Grain discharge wheel 9. Grain entrance hopper

10. attraction blower fan 11. Output screw conveyer |

|

Retarding section |

| Drying section |

Technical Parameters Technical Parameters

Item/Type |

LGG-15 |

LGG-30 |

LGG-45 |

LGG-60 |

Hoister |

Revolution (r/min) |

289.6 |

289.6 |

289.6 |

289.6 |

Output rate(t/h) |

5.69 |

5.69 |

5.69 |

15.28 |

Supportive power |

Power |

0.55 |

0.55 |

0.55 |

0.55 |

Lower screw conveyer |

Output rate(t/h) |

4.8 |

4.8 |

4.8 |

6.6 |

Revolution (r/min) |

160 |

160 |

160 |

160 |

Supportive power |

Power |

250w |

250w |

250w |

250w |

Functional parameters |

Charging time(imn) |

15.8 |

31.5 |

47.4 |

23.5 |

Discharging time (imn) |

20 |

40 |

60 |

60 |

Circulation period (imn) |

60 |

60 |

60 |

62 |

Fan |

Fan Type |

Tow-stage Axial-flow |

Tow-stage Axial-flow |

Tow-stage Axial-flow |

Centrifuge type |

Revolution (r/min) |

2000 |

2000 |

2000 |

1450 |

Supportive power(kW) |

1.1 |

1.1 |

1.1 |

4 |

|