Working Principle:

Working Principle:

The so-called vibration fluidized bed drier means that an exciting force with certain frequency is exerted on the fluidized bed, so that the fluidized bed will always keep vibration in a direction in the entire operation process.

The heating mode of vibration fluidized bed drier belongs to cross current drying according to the heating mode, heat energy is transferred to the surface of wet material in direct contact with it by hot air by means of cross i,e, Current, so as to conduct direct heating drying. The wet material is stirred up and down in the fluidized bed under the vibration force produced by hot air current with appropriate flow rate and vibration exciter. They are intermingled and collided, so that the charge layer on the bed surface keeps an even fluidization state that can move in a certain direction, so that ample mass transfer and heat transfer are conducted between wet material and hot air current, and reach the aim of drying.

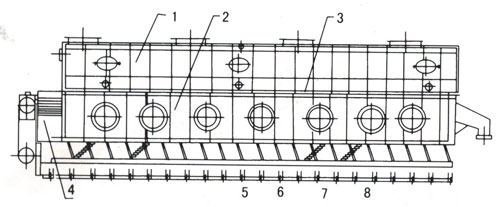

1. upper cavity 2. wind box 3. fluidized bed plate 4. box vibration exciter 5. base 6. flat spring 7. helical spring 8. rubber buffer

|

| 1. a section of air filter |

2. a section of wind blower |

| 3. a section of air heat exchanger |

4. two section of Air filter |

| 5. two section of wind blower |

6. two section of air heat exchanger |

| 7. cyclone duster |

8. Fan |

9. fine powder recovery blower fan |

|

|

Technical Parameters and Type:

Technical Parameters and Type:

Type |

GZS16×110 |

GZS12×120 |

GZS9×120 |

Bed surface length |

11000mm |

12000mm |

12000mmm |

Bed surface width |

1600mm |

1200mm |

900mm |

Vibration exciting frequency |

650/min |

650/min |

650/min |

Motor Power |

15KW |

11KW |

7.5KW |

Doulbe amplitude |

2-2.5mm |

2-2.5mm |

2-2.5mm |

Yield |

6500 tons/yr. |

5000 tons/yr. |

4000 tons/yr. |