Products

Contact us

Tel:0979-8967766 8960062

Fax:0979-8960062

Phone:13325776677

QQ:2293771507

Email:sales@qhldchem.com

URL:www.qhldchem.com

Fax:0979-8960062

Phone:13325776677

QQ:2293771507

Email:sales@qhldchem.com

URL:www.qhldchem.com

Products

Your current location:Home >> Products

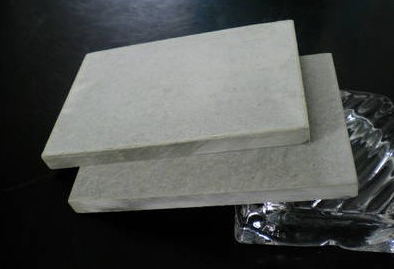

Magnesium oxychloride cement

Main performance

1、air hardening: Common gelling material takes cement as representatives, which are hardened in water, i.e. water hardened. Magnesium oxychloride cement is completely different with the conventional cement, which is one kind of air hardening, non-hardening in water. This is a prominent feature between Magnesium oxychloride cement and conventional cements.

2, multi-component: Magnesium oxychloride cement is a multi-component, single light burning magnesium powder is not hardened in water. Its one component is light burned magnesium dolomite ash, another component is magnesium salt , the other components are water and modifiers.

3, high heat release: Magnesium oxychloride cement can r elease high heat during curing . Its heat release is 1000 ~ 13500J/gMgO, the center temperature of the reaction system up to a maximum 140 ° C, in summer may exceed 150 ° C. Portland cement's hydration heat is only 300 ~ 400J / g cement, Magnesium oxychloride cement is 3 to 4 times that of ordinary cement hydration.

4, b corrosive for steel : Magnesium oxychloride cement mostly take magnesium chloride as blender, which contains large amounts of chloride ions, thus it is extremely corrosive to steel.

5, high strength: Magnesium oxychloride cement can easily reach 62.5MPa. General light burning magnesium compressive strength of cementitious materials can reach 62.5MPa more than most can reach 90MPa. In light burning magnesium can guarantee the quality, Magnesium oxychloride cement ratio is reasonable, in the case of scientific technology, you can also reach 140MPa. Tests showed that when the light burning magnesium powder and inorganic aggregate mass ratio of 1: 1, the day of its compressive strength up to 34MPa, flexural strength 9MPa. Compressive strength of 28 days is 142PMa, flexural strength is 26MPa.

6, high wear resistance: He is three times the wear resistance of ordinary portland cement. We have a brick with Magnesium oxychloride cement and ordinary portland cement 32.5, put together the conservation for 28 days after the wear test, ordinary portland cement brick mill anti length of 34.7mm, while the light burning powder made of brick mill anti length of only 12.1mm, equivalent to cement tile 1/3, and foreign test match. Therefore particularly suitable for the production of Magnesium oxychloride cement floor tiles and other high wear products, especially abrasives such as grinding block tiles and so on.

7, good resistance to high temperature or low temperature: at various inorganic cementitious materials, only Magnesium oxychloride cement along with that high temperature, and low temperature properties.

Light burning powder of MgO refractory major component is 2800 ° C, ranking first of all refractory magnesia used. Therefore, Magnesium oxychloride cement building materials generally have high temperature characteristics, even if the glass fiber composite can also be fire-resistant 300 ° C or more. Magnesium oxychloride cement precisely because of this fire resistance, it is widely used in the production of fire board.

Magnesium oxychloride cement not only the high temperature performance, low temperature performance is also excellent. Magnesium oxychloride cement mostly because magnesium chloride is to reconcile the agent, and magnesium chloride are antifreeze. Therefore, Magnesium oxychloride cement has a natural resistance to low temperature performance, so at low temperatures Magnesium oxychloride cement product can also be produced as usual, does not require additional antifreeze. In general, the -30 ° C low temperature resistance.

8, anti-corrosive brine: Magnesium oxychloride cement because it is made to reconcile with brine agent (mostly magnesium chloride), which means that it itself is the brine ingredients, so it is not afraid of brine corrosion, but also increase the strength of the case of brine. This makes it possible to overcome the deficiencies of ordinary cement and concrete products, for high-brine region.

9, air stability and weather resistance: Due Magnesium oxychloride cement is air hardening, and after the final setting of the air only to continue setting and hardening species, which it has a good stability in air, the drier the air, it is more stable .

Tests showed, Magnesium oxychloride cement products in dry air, which both compressive and flexural degrees and grow with age until the age of two is still growing, very stable. Also proved, Magnesium oxychloride cement strength in dry air is growing.

In addition, because Magnesium oxychloride cement with anti-high temperature performance, in hot weather and cold climates all have stability, climate change will not affect its stability. It is also excellent in weather resistance.

10, low alkalnine and corrosive: Magnesium oxychloride cement alkalinity cement is much lower than any conventional varieties. After testing, the pH of the filtrate slurry which fluctuated between 8-9.5, is very low close to neutral. Magnesium oxychloride cement because of low alkalinity only slightly alkaline, glass fiber and wood fiber corrosion is small. We all know that GRC glass fiber reinforced products, vegetable fiber products with sawdust, wood shavings, cotton stalks, bagasse, peanut shells, rice husks, corn scraps of wood fiber reinforced core powder, and glass fiber and wood fiber are non-alkali materials, extremely afraid of alkali corrosion, corrosion at high alkali they will lose strength, enhance the role of the cementitious material loss. Therefore, the conventional cement can not be due to the high base and wood fiber reinforced with fiberglass. The Magnesium oxychloride cement was slightly alkaline unique advantages in the areas of planting GRC fiber products in the field and flourish, and this is the main reason for it to become inorganic glass steel.

11, light and low density: Density Magnesium oxychloride cement products generally only 70% of ordinary Portland article, its density is generally products 1600 ~ 1800kg / m³, and the density of the cement products generally 2400 ~ 2500kg / m . So it has a very low density.

12, fast-solidified: Magnesium oxychloride cement with unsolicited fast condensable. After adding reconcile general agent, 4 ~ 8h release of strength can be achieved. Its initial setting is 35 ~ 45min, final setting 50 ~ 60min, the equivalent of rapid hardening cement. Fast-setting rapid hardening cement is applied procoagulant material, production process is complex, and Magnesium oxychloride cement is rapidly solidified material itself naturally formed.

13, good impermeability: Magnesium oxychloride cement can form a high density after setting and hardenin , pore phase is much less for conventional cement. Therefore, it has a good impermeability, seepage coefficient is very low;even not mixed with impermeability agent, it can reach S25 hardened over impermeability grade. Precisely because it's such a good impermeability, it has broad application prospects in the field of wave tile and other roofing materials.

14, high-gloss products: Use the same brightness abrasive, we made a conventional product with Magnesium oxychloride cement and cementitious materials; you will find, the glossiness of Magnesium oxychloride cement products are much higher than that of cement products.

1、air hardening: Common gelling material takes cement as representatives, which are hardened in water, i.e. water hardened. Magnesium oxychloride cement is completely different with the conventional cement, which is one kind of air hardening, non-hardening in water. This is a prominent feature between Magnesium oxychloride cement and conventional cements.

2, multi-component: Magnesium oxychloride cement is a multi-component, single light burning magnesium powder is not hardened in water. Its one component is light burned magnesium dolomite ash, another component is magnesium salt , the other components are water and modifiers.

3, high heat release: Magnesium oxychloride cement can r elease high heat during curing . Its heat release is 1000 ~ 13500J/gMgO, the center temperature of the reaction system up to a maximum 140 ° C, in summer may exceed 150 ° C. Portland cement's hydration heat is only 300 ~ 400J / g cement, Magnesium oxychloride cement is 3 to 4 times that of ordinary cement hydration.

4, b corrosive for steel : Magnesium oxychloride cement mostly take magnesium chloride as blender, which contains large amounts of chloride ions, thus it is extremely corrosive to steel.

5, high strength: Magnesium oxychloride cement can easily reach 62.5MPa. General light burning magnesium compressive strength of cementitious materials can reach 62.5MPa more than most can reach 90MPa. In light burning magnesium can guarantee the quality, Magnesium oxychloride cement ratio is reasonable, in the case of scientific technology, you can also reach 140MPa. Tests showed that when the light burning magnesium powder and inorganic aggregate mass ratio of 1: 1, the day of its compressive strength up to 34MPa, flexural strength 9MPa. Compressive strength of 28 days is 142PMa, flexural strength is 26MPa.

6, high wear resistance: He is three times the wear resistance of ordinary portland cement. We have a brick with Magnesium oxychloride cement and ordinary portland cement 32.5, put together the conservation for 28 days after the wear test, ordinary portland cement brick mill anti length of 34.7mm, while the light burning powder made of brick mill anti length of only 12.1mm, equivalent to cement tile 1/3, and foreign test match. Therefore particularly suitable for the production of Magnesium oxychloride cement floor tiles and other high wear products, especially abrasives such as grinding block tiles and so on.

7, good resistance to high temperature or low temperature: at various inorganic cementitious materials, only Magnesium oxychloride cement along with that high temperature, and low temperature properties.

Light burning powder of MgO refractory major component is 2800 ° C, ranking first of all refractory magnesia used. Therefore, Magnesium oxychloride cement building materials generally have high temperature characteristics, even if the glass fiber composite can also be fire-resistant 300 ° C or more. Magnesium oxychloride cement precisely because of this fire resistance, it is widely used in the production of fire board.

Magnesium oxychloride cement not only the high temperature performance, low temperature performance is also excellent. Magnesium oxychloride cement mostly because magnesium chloride is to reconcile the agent, and magnesium chloride are antifreeze. Therefore, Magnesium oxychloride cement has a natural resistance to low temperature performance, so at low temperatures Magnesium oxychloride cement product can also be produced as usual, does not require additional antifreeze. In general, the -30 ° C low temperature resistance.

8, anti-corrosive brine: Magnesium oxychloride cement because it is made to reconcile with brine agent (mostly magnesium chloride), which means that it itself is the brine ingredients, so it is not afraid of brine corrosion, but also increase the strength of the case of brine. This makes it possible to overcome the deficiencies of ordinary cement and concrete products, for high-brine region.

9, air stability and weather resistance: Due Magnesium oxychloride cement is air hardening, and after the final setting of the air only to continue setting and hardening species, which it has a good stability in air, the drier the air, it is more stable .

Tests showed, Magnesium oxychloride cement products in dry air, which both compressive and flexural degrees and grow with age until the age of two is still growing, very stable. Also proved, Magnesium oxychloride cement strength in dry air is growing.

In addition, because Magnesium oxychloride cement with anti-high temperature performance, in hot weather and cold climates all have stability, climate change will not affect its stability. It is also excellent in weather resistance.

10, low alkalnine and corrosive: Magnesium oxychloride cement alkalinity cement is much lower than any conventional varieties. After testing, the pH of the filtrate slurry which fluctuated between 8-9.5, is very low close to neutral. Magnesium oxychloride cement because of low alkalinity only slightly alkaline, glass fiber and wood fiber corrosion is small. We all know that GRC glass fiber reinforced products, vegetable fiber products with sawdust, wood shavings, cotton stalks, bagasse, peanut shells, rice husks, corn scraps of wood fiber reinforced core powder, and glass fiber and wood fiber are non-alkali materials, extremely afraid of alkali corrosion, corrosion at high alkali they will lose strength, enhance the role of the cementitious material loss. Therefore, the conventional cement can not be due to the high base and wood fiber reinforced with fiberglass. The Magnesium oxychloride cement was slightly alkaline unique advantages in the areas of planting GRC fiber products in the field and flourish, and this is the main reason for it to become inorganic glass steel.

11, light and low density: Density Magnesium oxychloride cement products generally only 70% of ordinary Portland article, its density is generally products 1600 ~ 1800kg / m³, and the density of the cement products generally 2400 ~ 2500kg / m . So it has a very low density.

12, fast-solidified: Magnesium oxychloride cement with unsolicited fast condensable. After adding reconcile general agent, 4 ~ 8h release of strength can be achieved. Its initial setting is 35 ~ 45min, final setting 50 ~ 60min, the equivalent of rapid hardening cement. Fast-setting rapid hardening cement is applied procoagulant material, production process is complex, and Magnesium oxychloride cement is rapidly solidified material itself naturally formed.

13, good impermeability: Magnesium oxychloride cement can form a high density after setting and hardenin , pore phase is much less for conventional cement. Therefore, it has a good impermeability, seepage coefficient is very low;even not mixed with impermeability agent, it can reach S25 hardened over impermeability grade. Precisely because it's such a good impermeability, it has broad application prospects in the field of wave tile and other roofing materials.

14, high-gloss products: Use the same brightness abrasive, we made a conventional product with Magnesium oxychloride cement and cementitious materials; you will find, the glossiness of Magnesium oxychloride cement products are much higher than that of cement products.

Uses

1, for the production of building materials: Firewood (magnesium glass plate), lightweight wall, magnesite well covers, magnesite tile, ventilation ducts, trailer coach, greenhouses stents.

2, for the production of decorative materials: fire doors, stone-imitating ornament, art relief flower pots, artistic fountains, large rockery, antique large door lion, bins, culture stone and cultural brick, artistic railings, home or large assembly barn.

3, for the production of packaging materials: trays, electrics, instruments, large wood boxes, crates and other package boxes of mechanical equipment

4, for the production of transport facilities: roads shelters, police kiosks, street seat rails, bridge rails, light poles, etc.

5, for the production of handicrafts: animal & human handicrafts, flower pots, wall hangings, glass frame, urn, park chairs, Roman column, wood-imitating furniture, bird feeders, plates, audio products, garden ornaments series.

6, for the production of chemical materials: desulfurization, magnesium sulfate, selenium soil.

7, for the production of other products: abrasive tools, gas cans, lead fixing agent of firecrackers.

2, for the production of decorative materials: fire doors, stone-imitating ornament, art relief flower pots, artistic fountains, large rockery, antique large door lion, bins, culture stone and cultural brick, artistic railings, home or large assembly barn.

3, for the production of packaging materials: trays, electrics, instruments, large wood boxes, crates and other package boxes of mechanical equipment

4, for the production of transport facilities: roads shelters, police kiosks, street seat rails, bridge rails, light poles, etc.

5, for the production of handicrafts: animal & human handicrafts, flower pots, wall hangings, glass frame, urn, park chairs, Roman column, wood-imitating furniture, bird feeders, plates, audio products, garden ornaments series.

6, for the production of chemical materials: desulfurization, magnesium sulfate, selenium soil.

7, for the production of other products: abrasive tools, gas cans, lead fixing agent of firecrackers.