|

|

|

| |

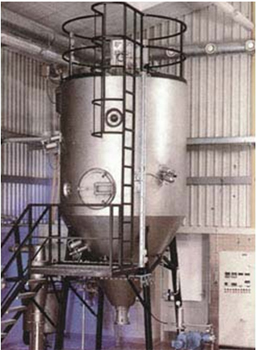

| LPG series High-speed centrifugal spray drying machine |

| |

|

| |

|

Air passing through the heater into hot air into the device in the drying room at the top of the hot air distributor, then evenly into the drying chamber, and a spiral rotation, and sends the material liquid to the top of the drying chamber of centrifugal atomizer, the feed liquid is sprayed into little fog droplet, liquid and hot air flow, and contact rapid evaporation of moisture, in a very short time drying for powder. Simple operation, convenient control, easy realization of automatic operation.

|

|

|

|

| Air passing through the heater into hot air into the device in the drying room at the top of the hot air distributor, then evenly into the drying chamber, and a spiral rotation, and sends the material liquid to the top of the drying chamber of centrifugal atomizer, the feed liquid is sprayed into little fog droplet, liquid and hot air flow, and contact rapid evaporation of moisture, in a very short time drying for powder. Finished bottom of the drying tower and cyclone exhaust, exhaust gas by fan out emptying.

|

|

|

|

- Quick drying speed, feed liquid atomization, specific surface area is greatly increased, in the hot air of flash evaporation of water can be 65-95%, drying time is only several seconds to tens of seconds, especially suitable for heat-sensitive materials drying.

- The product is the spherical particle, particle size uniformity, good fluidity, good solubility, high purity, good quality.

- Simple operation, convenient control, easy realization of automatic operation.

- The production process is simplified, the operation environment and health.

|

|

|

|

The chemical industry : sodium fluoride ( k ), alkaline dye pigments, dyes intermediates, compound fertilizer, formaldehyde, silicate, sulfuric acid catalyst agent, amino acid, white carbon black.

The plastic resin: AB, ABS emulsion, urea-formaldehyde resin, phenolic resin, sealing glue ( urea ) formaldehyde resin, polyethylene, polyvinyl chloride.

Food industry: rich fat milk powder, milk powder, cocoa. Prion, milk replacer, a blood meal, egg please ( yellow ).

Food and vegetable: oats, chicken juice, coffee, instant tea, spices, meat protein, soybean, peanut protein, hydrolysate.

Effects of carbohydrate : corn syrup, corn starch, pectin, glucose, maltose, potassium sorbate.

The ceramic tile: alumina, material, magnesium oxide, talc powder.

|

|

|

|

Item

Model |

5 |

25 |

50 |

100 |

150 |

200 |

300 |

500 |

Temperature of air at Inlet (℃) |

350 |

Temperature of air at outlet (℃) |

80-90 |

Max Evaporation capacity (kg/h) |

5 |

25 |

50 |

100 |

150 |

200 |

300 |

500 |

Drive form of Centrifugal spray head |

Compressed air |

Mechanical drive or electric |

Diameter of spray tray (mm) |

50 |

102 |

108 |

108 |

150 |

150 |

180 |

180 |

Evaporation capacity (kg/h) |

5 |

25 |

50 |

100 |

150 |

200 |

500 |

800 |

Spray type |

High speed centrifugal atomizer |

Rev. of atomizer(r/min) |

25000 |

18000 |

16000 |

Diameter of Atomizing disc (mm) |

60 |

120 |

150 |

Diameter of tower (m) |

0.9 |

1.75 |

2.3 |

2.7 |

3 |

3.8 |

4.7 |

5.6 |

Length (m) |

1.6 |

4 |

4.5 |

5.2 |

7 |

7.5 |

12.5 |

13.5 |

Width (m) |

0.91 |

2.7 |

2.8 |

3.5 |

5.5 |

6 |

8 |

12 |

Height (m) |

1.75 |

4.5 |

5.5 |

6.7 |

7.2 |

8 |

10 |

11 |

Lift Height of spray head (m) |

|

2.5 |

2.5 |

3.2 |

3.2 |

3.2 |

3.2 |

3.2 |

Heat sources |

Electricity, electricity and steam, hot blast stove, natural gas, etc |

|

|

|

|

|

|

|

|

|

Please fill this form if you want more details of our products. (please fill your information properly) Please fill this form if you want more details of our products. (please fill your information properly) |

|

| |

| |

|

|

|

|