|

|

|

| |

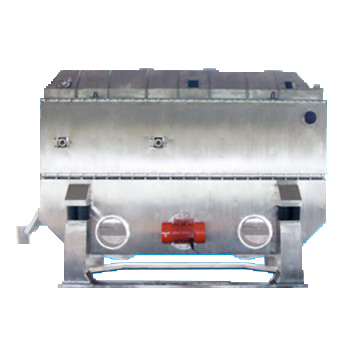

| ZG series Multi-layer vibration Fluidized bed |

| |

|

| |

|

ZG series multilayer vibrating fluidized bed dryer by two vibration motors has forced vibration, wet material along the upper sieve plate tilt direction in vibration and hot formed under the influence of fluidization forward, wet material in the upper plate heat gain is hot air through the lower material heat exchange after the rest. The multilayer sieve material, heat energy fully utilized, after drying by the discharge valve discharge. Exhaust gas from the cyclone separator and trap by induced draft fan.

|

|

|

|

The air passing through the filter, is heated by the heater and adjust it to the desired temperature, hot air into the bottom of the dryer. Material by screw conveyor ( also can choose other transportation mode ) is transported to the dryer inlet.

Dryer by two vibration motors has forced vibration, wet material along the upper sieve plate tilt direction in vibration and hot formed under the influence of fluidization forward, wet material in the upper plate heat gain is hot air through the lower material heat exchange after the rest. The multilayer sieve material, heat energy fully utilized, after drying by the discharge valve discharge. Exhaust gas from the cyclone separator and trap by induced draft fan.

|

|

|

|

- Energy saving: hot air passes through multilayer sieve and dry material heat exchange, energy saving 40%-60% than single fluidized bed.

- The operation is simple and convenient: in the machine, the thickness of the material layer, material moving speed can be adjusted. The material in the drying time, adjusted according to requirement, moisture control.

- Dry matter weight high: the fluidized bed temperature distribution is uniform, avoiding the product of any local overheating. The material on the bed layer formed in the piston flow, to overcome the ordinary fluidized bed of back mixing phenomenon, so that even drying of the material. Material surface wear small, fragile, can be used for keeping the integrity of materials drying.

- Exclusive main air inlet device:

1, the device can make just in the fluidized bed material is quickly dispersed and uniformly distributed, not bonded plate, does not appear empty bed and bed death phenomenon.

2, high temperature hot and high wet material full contact, quick moisture evaporation.

- Angle of the motor rotation: vibration motor assembly form vibration motor is installed horizontally, the vibration motor flange through the center tube connection, two vibrating motor with four root through bolt dynamic connection, and has the advantages of high strength, good adjustable, flange and the box body is not easy broken etc..

- Small area: relative monolayer fluidized bed equipment volume can be reduced by 1/2-2/3.

|

|

|

|

Name of Material |

Status |

Initial moisture

(%) |

The final moisture

(%) |

Name of Material |

Status |

Initial moisture

(%) |

The final moisture

(%) |

Bronopol |

Crystal particles |

3.0 |

0.2 |

Sodium dihydrogen phosphate |

Crystals |

5.0 |

0.5 |

Potassium sulfate |

Powdered |

4.0 |

0.5 |

Sulfamate |

Crystal |

1.1 |

0.05 |

Sodium bromide (potassium) |

Crystal particles |

3.0 |

0.2 |

NPK fertilizer |

Spherical |

24.4 |

5.5 |

Ammonium persulfate |

Powdered |

3.5 |

0.08 |

Bentonite |

Powdered |

20.5 |

0.5 |

Thiourea |

Grain |

3.0 |

0.28 |

Aluminum hydroxide |

Powdered |

30 |

1 |

Thiamine |

Grain |

3.0 |

0.2 |

Washing powder |

Powdered |

43.7 |

18.0 |

Pentaerythritol |

Powdered |

20.0 |

0.5 |

Citric acid |

Crystal particles |

2.5 |

0.5 |

Azobisisobutyronitrile Clear |

Crystals |

2.0 |

0.1 |

Potassium citrate |

Crystal particles |

2.5 |

0.5 |

Potassium permanganate |

Grain |

5.0 |

0.1 |

Salt |

Granular |

4.0 |

0.5 |

Sebacic acid |

Needle-like crystals |

9.25 |

0.15 |

Chinese Herbal Medicine |

Sheet |

58.0 |

4.0 |

Barium chloride |

Crystal |

5 |

0.5 |

Polyether ether ketone |

Granular |

50 |

0.03 |

Activated Carbon |

Powdered |

80 |

5 |

Polyphenylene sulfide |

Granular |

50 |

0.03 |

Activated Carbon |

Powders, granules |

50 ~ 60 |

6.0 |

Polyether ether nitrile |

Granular |

50 |

0.03 |

Sodium nitrate |

Crystal |

5 |

1 |

Door radon acid |

Crystal particles |

5 to 7 |

0.2 |

MSG |

Crystal particles |

5.0 |

0.2 |

Phenylacetic acid |

Crystal particles |

10 |

0.2 |

|

|

|

|

Model

Item |

ZG-18 |

ZG-24 |

ZG-36 |

ZG-40 |

ZG-50 |

ZG-60 |

ZG-75 |

ZG-108 |

ZG-140 |

ZG-180 |

Bed area (m2) |

1.8 |

2.4 |

3.6 |

4.0 |

5.0 |

6.0 |

7.5 |

10.8 |

14 |

18 |

Moisture Evaporation (kg/h) |

108 |

144 |

216 |

255 |

318 |

336 |

372 |

688 |

892 |

1150 |

Vibration force (kN) |

18×2 |

25×2 |

50×2 |

50×2 |

50×2 |

60×2 |

60×2 |

75×2 |

100×2 |

130×2 |

Vibration frequency |

960次/min |

Total Power (kW) |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

70 |

100 |

120 |

Size of Sieve plate

(m) |

L |

3 |

3 |

4.5 |

4 |

5 |

6 |

5 |

6 |

7 |

8.5 |

W |

0.6 |

0.8 |

0.8 |

1 |

1 |

1 |

1.5 |

1.8 |

2 |

2.2 |

H |

upon the angle of Sieve plate |

Weight |

upon the angle of Sieve plate |

|

|

|

|

|

|

|

|

|

|

Please fill this form if you want more details of our products. (please fill your information properly) Please fill this form if you want more details of our products. (please fill your information properly) |

|

| |

| |

|

|

|

|