|

|

|

| |

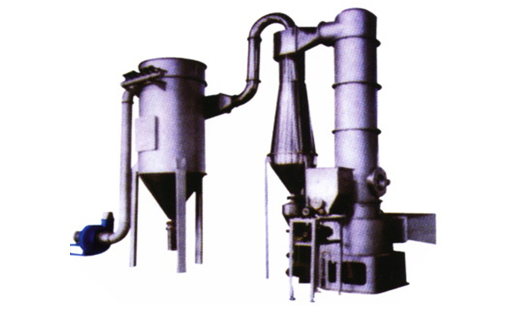

| SXG Rotating and flashing drying machine |

| |

|

| |

|

Flash drying is a crushing device of vertical fluidized bed dryer can be completed at the same time, drying, crushing, grading and other operations. Device body is a cylindrical drying chamber, from the bottom of the pulverizing fluidized drying section, middle section, top grade section. The bottom crushing section is provided with a mixer, stirrer speed by adjusting external motor speed regulation. The agitator has two effects, driven from the distribution chamber into the chamber to dry hot air to produce high-speed rotation airflow to form a fluidized layer.

|

|

|

|

According to the structure of spin flash dryer, can take the work process is divided into pieces, gas-solid contact, drying, grading of four stages, the four working process is not at the same time with the other dryer.

1 broken

Because the primary flash dryer for drying paste-shaped materials, the material into the dryer immediately after being exposed to a stirring blade and high-speed airflow crusher, to maximize the material dispersion and wet material surface area per unit volume.

2 gas solid mixing

Flash dryer with air as heat carrier, can effectively achieve the gas-solid mixing is the main factor affecting the drying rate. Flash dryer stirring paddle to crushing and dispersion effect, at the same time into drier air in a highly turbulent state, quickly reaches the gas solid mixing. At the same time, the bulk of materials under the action of gravity downward fall, due to the bottom of the dryer for inverted cone structure, the gas velocity, the maximum is 60ni/s. To ensure good bulk material in fluidized state and is surrounded by hot air.

3 stage of drying

The material crushing, be come from the bottom of high speed rotating hot air flow blows in the drying chamber, formed a relatively stable fluidized layer. In the material and the hot air between heat and mass transfer of the drying process, most of the water at this stage evaporation. High moisture content, small surface area of the material density, in the drying chamber downward fall, as the bottom of the gas velocity is high, falling to a certain distance after falling speed is zero, the gravity and buoyancy balance. The material is further broken and water evaporation after the buoyancy is greater than the gravity, the material begins to move upward, through the classification after the discharge of dryer.

4 grade phase

Grading device is installed in the dryer at the top of the annular baffle, due to the effect of centrifugal force, the material with the air up process, large, wet material rotary radius increases, when the rotating radius is larger than the grading ring radius is blocked in the drying room, until meet requirements can be discharged through the grading machine dryer. When the material is added to the dryer, material in rotary fluidization. Mass by crushing diameter decreases rapidly, the moisture is evaporated. The material in the gas entrainment under the spiral motion, smaller particle diameter than the dry material in the inner ring, large and damp material produce large centrifugal force in the outer layers near the wall. But the large particles are being crushed dry, centrifugal force become smaller after also to the inner movement, when the water meet the requirements after the gas out of.

Rotation radius and pressure is the relationship between the radius of rotation is small, the lower the pressure. In the center of pressure of drying chamber, the lowest, in the zone near the wall pressure maximum. For small diameter particles, due to the pressure as the radius increases, the radial pressure distribution, small particles to the center of motion, large particles from the inside to the outside edge of sports dryer. Therefore the dried particles are trapped air from the drying chamber with a center, whereas larger particles along the edge of the upward movement was graded ring block can not escape, thereby ensuring the product moisture and particle size uniformity.

|

|

|

|

- This machine integrates drying, crushing, grading in one, to the use of a machine, simplifies the production process, reduces the material consumption, reduce the labor intensity of scattered.

- The equipment is compact, small size, high production efficiency, continuous operation, the realization of a small equipment, production.

- Dry strength, low energy consumption, thermal efficiency can reach more than 70%.

- Short residence time, good product quality, can be used for drying heat-sensitive materials.

- Negative pressure or negative pressure operation, good tightness, sanitation of production environment.

- Drying tower cleaning design is reasonable, the cleaning is convenient.

- Stirring device is installed, the disassembly is very convenient, to overcome the other dryer to drying tower to repair defects in.

- Stirring device of shaft seal of advanced design, solves the problem of shaft seal leakage powder.

|

|

|

|

The machine is suitable for the paste, paste, powder granular material drying.

Organic matter: atrazine ( pesticides ), lauric acid, benzoic acid, benzoic acid, sodium oxalate, such as cellulose acetate.

Dye: anthraquinone, black iron oxide, indigo, butyric acid, hydrogen oxidation titanium, zinc sulfide, all kinds of azo dye intermediates, phthalocyanine blue, blue, curing Pu aluminum chrome yellow, basic flavine.

Dye: anthraquinone, black iron oxide, indigo, butyric acid, hydrogen oxidation titanium, zinc sulfide, all kinds of azo dye intermediates, phthalocyanine blue, blue, curing Pu aluminum chrome yellow, basic flavine.

Ceramics, silicon dioxide, such as: Kaolin clay.

Food: soy protein, gelatinized starch, wheat grains, sugar, wheat starch.

Waste: biological mud, iron manganese slag, furfural residue.

Hard salt series: calcium ( magnesium, aluminum, zinc, barium, aluminum, chromium, two ) dibasic aluminum phosphate, three basic aluminum sulfate.

Organic chemicals: melamine, three phenyl tin acetate, benzoic acid, methyl cellulose, bromamine acid, DSD acid, 2,4-D acid, acid, acid I.

Pesticide: Bataan, monosultap, mancozeb, scan over net, destroy Do-win, quizalofop-p-ethyl, Tricyclazole, mefenacet, Paclobutrazol, atrazine, ametryn, of insects.

|

|

|

|

Specifications

Model |

Diameter of cylinder

(mm) |

Size

(mm) |

Power

(kW) |

Airflow

(m3/h) |

Moisture on Evaporation

(kg/h) |

Floor space

(mm2) |

SXG-200 |

200 |

Φ250×2800 |

0.75-2.2 |

300-800 |

10-20 |

3500×2500 |

SXG-300 |

300 |

Φ400×3300 |

3-4 |

600-1500 |

20-50 |

3800×2700 |

SXG-400 |

400 |

Φ500×3500 |

4-7.5 |

1250-2500 |

25-70 |

4000×3000 |

SXG-500 |

500 |

Φ600×4000 |

5.5-11 |

1500-4000 |

30-100 |

4200×3200 |

SXG-600 |

600 |

Φ700×4200 |

7.5-18.5 |

2500-5000 |

40-200 |

4250×3250 |

SXG-800 |

800 |

Φ900×4600 |

11-18.5 |

3000-8000 |

60-600 |

4500×3500 |

SXG-1000 |

1000 |

Φ1100×5000 |

15-30 |

5000-12500 |

100-1000 |

4750×3700 |

SXG-1200 |

1200 |

Φ1300×5200 |

15-37 |

1000-20000 |

150-1300 |

5000×4000 |

SXG-1400 |

1400 |

φ1500×5400 |

30-55 |

14000-27000 |

200-1600 |

5250×4250 |

SXG-1600 |

1600 |

Φ1700×6000 |

45-75 |

18700-36000 |

250-2000 |

5500×4500 |

|

|

|

|

|

|

|

|

|

Please fill this form if you want more details of our products. (please fill your information properly) Please fill this form if you want more details of our products. (please fill your information properly) |

|

| |

| |

|

|

|

|