|

|

|

| |

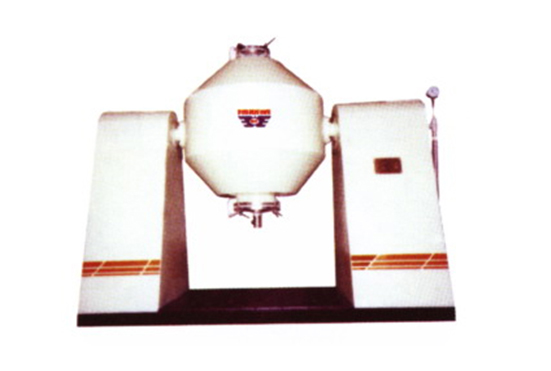

| SZG non-leakage Double-cone Vacuum drying machine |

| |

|

| |

|

1, unique sealing structure

Principle: a liquid inlet pipe through the liquid (gas ) tube flange and cylinder flange connection, the outer end of the packing seal, the leakage possibility minimum.

Advantage.:

To put an end to the inner leakage.

Adopting the outer sealing form, easy to find.

repair convenience : the traditional methods of leakage in cylinder must be found after hanging from the frame, tearing down the barrel shaft, replace the seals, is very difficult, and I plant the use of form, only to press the packing, in a very short period of time to complete, will not affect the normal production.

2, vacuum suction type for improvement

General double cone in the long-term use, suction head is constantly cylinder body turned up material flapping, resulting in vacuum tube bending deformation, deformation after the vacuum tube can not be very good sealing, causing the vacuum drops, even suction head and the vacuum tube welding fracture, in order to reduce the filtration area, reduce the suction head height, I plant will be rounded into a prismatic, to reduce the material and the filter head tapping area can be improved, avoiding the above problems.

3, with quick connectors

Inlet valve and a quick joint, feeding only on the hose, can carry out vacuum pumping material, fast and convenient, can greatly reduce labor intensity.

|

|

|

|

| Double cone rotary vacuum dryer set mixing and drying in one of the new type dryer. Condenser, vacuum pump and dryer supporting, composed of vacuum drying device. Cone rotating within the canister vacuum state, to the inside of the jacket into the steam or hot water heating, heat through the tank wall and the wet material contact, wet material after heat absorption evaporation of water vapor, the vacuum pump vacuum exhaust pipe is pumped out. Because the inner of tank is in a vacuum state, and the can body rotary material continuously up and turning, thus accelerate the drying speed of the material, improving the drying efficiency, achieve the purpose of uniform dry.

|

|

|

|

- Advanced design is reasonable, convenient installation and debugging, can adapt to a variety of conditions for. A continuous protective device.

- Can reduce the labor intensity and improving work environment

- The material in water can be flexible regulation

- In the vacuum cryogenic environment the whole drying process is completed, with medical GMP standard, and is suitable for heat-sensitive materials.

- A high degree of automation, simple internal structure, easy cleaning, simple operation, and can continuous production.

- Equipment repair has the advantages of simple operation, easy cleaning.

|

|

|

|

This machine is suitable for pharmaceutical, food, chemical industries such as powder granular material drying and mixing, especially has the following requirements materials:

The temperature of the heat sensitive material does not contact.

The easily vaporized material.

Study on crystallization does not allow the destruction of the material.

The recovery of residual volatile material.

The exhaust steam recovery when dry material.

Effect of strong stimulation, toxic materials.

|

|

|

|

Model

Item |

SZG100 |

SZG350 |

SZG500 |

SZG750 |

SZG1000 |

SZG1500 |

SZG2000 |

SZG3000 |

SZG4500 |

Total Volume (L) |

100 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3000 |

4500 |

Operating Volume (L) |

500 |

175 |

250 |

375 |

500 |

750 |

1000 |

1500 |

2250 |

Heating area (m2) |

1.16 |

2 |

2.63 |

.5 |

4.61 |

5.58 |

7.5 |

9.6 |

13.8 |

Rev. (rpm) |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

4 |

4 |

Power (kw) |

0.45 |

1.5 |

1.5 |

2 |

3 |

4 |

5.5 |

7.5 |

11 |

Rotary speed (mm) |

1600 |

1930 |

2060 |

2160 |

2260 |

2760 |

3160 |

3500 |

4150 |

Design pressure in the cylinder (MPa) |

-0.1-0.15 |

Design pressure in the jacket (MPa) |

0.3 |

|

|

|

|

|

|

|

|

|

Please fill this form if you want more details of our products. (please fill your information properly) Please fill this form if you want more details of our products. (please fill your information properly) |

|

| |

| |

|

|

|

|