|

|

|

| |

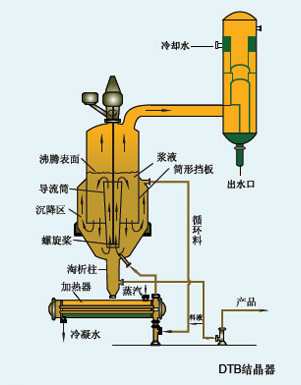

| DBT Type evaporation crystallizer |

| |

|

| |

|

DTB evaporation crystallizer referred to as shade guide type crystallizer, is a kind of efficient crystallization equipment. This type of mold can produce larger particles, the production of high strength, is not easy scaling. It has become one of the main forms of continuous crystallizer, can be used for vacuum cooling, evaporation method, direct contact freezing and crystallization reaction method. Operation control crystallization removal rate, seed addition rate and stirring speed and balance relation.

|

|

|

|

| DTB mold has a central draft tube, around a cylindrical baffle. In the flow-guiding barrel near the lower end of a propeller ( also can be seen as internal circulating axial flow pump ), with low rotation speed. Suspension in the propeller drive below, in the tube rises to the liquid surface, and then shifted beneath, along the guide shell and the baffle between the annular channel flow to the container bottom, again the flow guiding cylinder is, so cycle, form close to good mixing conditions. Cylindrical baffle will mold divider for crystal growth area and clarifying zone. Baffle wall and the annular space between for clarifying zone, in which the influence of mixing has virtually disappeared, the crystals are from the mother liquor in settlement and separation, only the excess microcrystalline mother liquid in clarifying area is discharged at the top of reactor, thus realizing the crystallite volume control. The upper part of the mould for the vapor-liquid separation space, used to prevent entrainment. Hot concentrated materials to guide tube is composed of crystallizer, slurry from the bottom.

|

|

|

|

- Is a kind of typical slurry circulation type crystallizer;

- The fluid dynamics has good effect, high production efficiency;

- Development of special screw, realize efficient internal circulation, and almost not a two nucleation;

- Draft tube and inner wall polishing, rarely scarring phenomenon;

- Slurry supersaturation of uniform particle size distribution, good, to achieve high efficiency;

- Install the elutriation leg to realize continuous production operation;

- Low speed, easy regulation, strong applicability, reliable operation, less faults.

|

|

|

|

DTB evaporation crystallizer are widely used in chemical industry, food, pharmaceutical and other industrial sectors.

Applicable to sodium chloride, potassium chloride, barium chloride, ammonium chloride, sodium nitrate, boric acid, glutamate, MSG, citric acid, L- lysine hydrochloride and glucose Vc, xylitol, and other products of continuous crystallization process, at the same time, widely used in chemical industry, food, pharmaceutical and other industrial sectors.

|

|

|

|

Item |

DTB-1000 |

DTB-1200 |

DTB-1400 |

DTB-1600 |

DTB-1800 |

DTB-2000 |

Evaporation capacity (kgH2O) |

|

|

|

|

|

|

Heat exchange area (㎡) |

|

|

|

|

|

|

Jacketed area (㎡) |

|

|

|

|

|

|

Cooling media |

Water or refrigerating fulid |

Consumption of cooling-water (m3/h) |

|

Steam pressure (MPa) |

≤0.3 |

Gas consumption (㎏/h) |

|

|

|

|

|

|

Power of Main stirring (kW) |

|

|

|

|

|

|

Power of Circulating pump (kW) |

1.5 |

2.2 |

3 |

4 |

5.5 |

7.5 |

Power of feeding pump (kW) |

|

|

|

|

|

|

Diameter of heater (mm) |

|

|

|

|

|

|

Diameter of flow guide tube (mm) |

|

|

|

|

|

|

Diameter of Crystallizer (mm) |

|

|

|

|

|

|

Height of Crystallizer (mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Please fill this form if you want more details of our products. (please fill your information properly) Please fill this form if you want more details of our products. (please fill your information properly) |

|

| |

| |

|

|

|

|