|

|

|

| |

| Drying production line of Sodium nitrate |

| |

|

| |

|

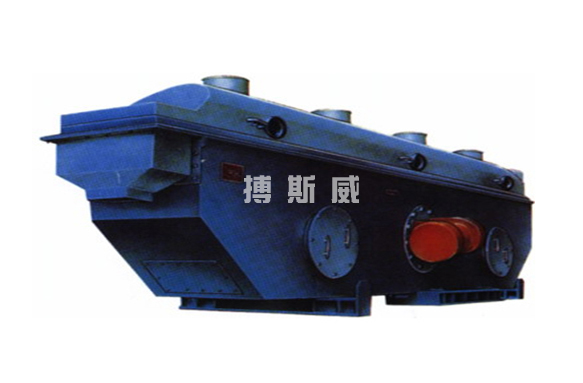

Using DG series linear vibrating fluidized bed dryer, material from the feed into the machine, under the action of vibration force, material along the horizontal direction forward throw, continuous motion, hot air upward through the fluidized bed with wet material heat, humid air by the cyclone dust from the discharging outlet, dry material from the discharge outlet.

|

|

|

|

Tongliao coal chemical industry limited company

Kim Yong Puyang chemical industry limited company

Kim Yong Yongcheng chemical industry limited company

Kim Yong Xinxiang chemical industry limited company

Kim Yong Anyang chemical industry limited company

|

|

|

|

- Due to the application of vibration, the mean flow speed is reduced, which can significantly reduce the amount of air required, thereby reducing the dust entrained, matching pieces of corresponding specifications shrinking, complete sets of equipment cost, obvious energy saving effect.

- Can be convenient to rely on the adjustment of vibration parameter to change material organic retention time. The piston flow dynamic line reduces the particle size uniformity and regularity requirements, the easy to obtain uniform drying products.

- Vibration is beneficial to the dispersion of the material, improve the drying effect.

- Because there is no intense mixing, flow rate than ordinary fluidized bed is also low, small damage to the material particles.

- Uniform heating of materials, sufficient heat exchange, high dry strength.

- Vibration source adopts vibration motor drive, smooth motion, convenient repair, low noise.

- Cloth uniform fluidization is smooth, no dead angle and blown through phenomenon.

- It is good, the thickness of the material layer and movable speed inside the machine and the amplitude can realize stepless adjustment.

- Can be completed at the same time drying and cooling of two processes, one machine with multifunction and convenient operation.

|

|

|

|

| Material from the feeder into the dryer, under the action of exciting force and to under on hot air under the common action of material along the horizontal direction, the fluidized bed throw forward continuous motion, hot air upward through the fluidized bed plate with material for heat and mass transfer, reaching for the purpose of drying, according to production needs to be drier is divided into two sections, the first half of part with hot air to dry, the second part of the material with high temperature air cooling, to packaging requirements. Wet air by the cyclone dust collector as exhaust gas, dry materials from the discharge port.

|

|

|

|

Jiangsu Bosiwei Engineering Technology Co., Ltd. has twenty-six years of industry experience in production of evaporator, designed products, with superb processing technology, a rich field installation experience and perfect after sale service system, wholeheartedly for customer service.

In the production process, equipment of the design drawings; equipment manufacturing process in a timely manner to customer communications equipment production speed, production quality, and ensure customer engineering progress and equipment manufacturing production synchronization; equipment installation for technical staff to the scene to guide the installation, commissioning, acceptance and technical training and other services of the entire process.

|

|

|

|

|

|

|

|

| |

|

Related data download |

|

|

|

| |

|

|

|

| |

|

|

|

|